Custom Low

Custom Low-Volume Injection Molding for Food Grade Liquid Silicone Low-Volume Injection Molding, also known as LSR & Liq

Description

Basic Info.

| Model NO. | LSR-10 |

| Mold Steel | S136 Heat Treatment, Lkm, 718h |

| Machine Type | Horizontal, Vertical |

| Properties | Biocompatibility, Low Compression Set,FDA Grade |

| Applications | Infants Products, Medical Devices, Electronic, etc |

| Runner | Cold Runner |

| Standard | FDA, RoHS, SGS, Igs |

| Tolerance | -/+0.01mm |

| Surface Finish Process | Polishing |

| Plastic Material | Thermosetting |

| Color | High Transparent |

| Transport Package | Poly Bags, Carton Boxes |

| Specification | Customized |

| Trademark | Better |

| Origin | Xiamen, China |

| HS Code | 847740900 |

| Production Capacity | 50sets/Month |

Product Description

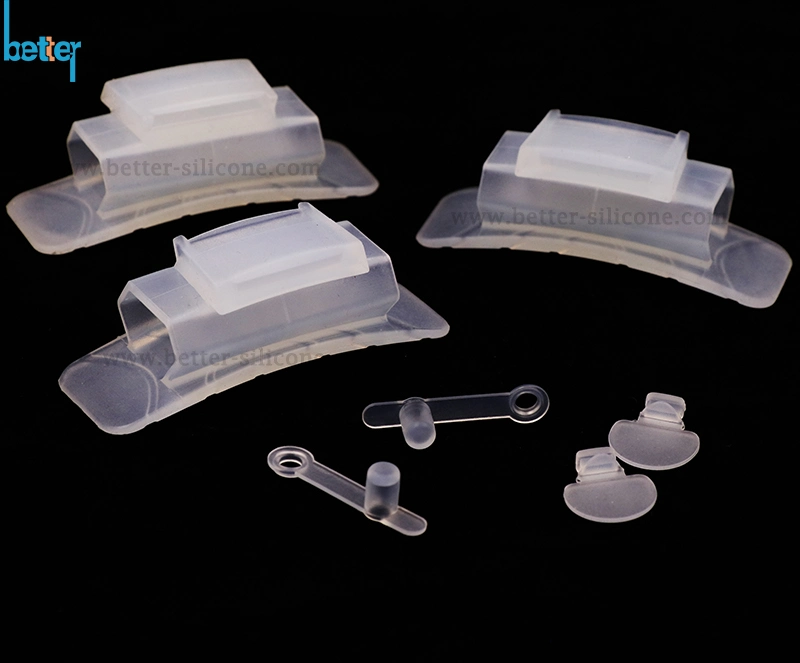

Custom Low-Volume Injection Molding for Food Grade Liquid Silicone

Low-Volume Injection Molding, also known as LSR & Liquid Silicone Rubber Molding and LSR Injection Molding (LIM) & Silicone Injection Molding, is a process to pump the high purity platinum cured silicone (supplied in barrels: A + B components at 1:1) through a static mixer for into the heated cavity and vulcanized, which is suitable for the production requiring high quality, high precision and high volume.Low-Volume Injection Molding is typically applied for sealing membranes, electronics, infant products, medical products and overmolded products, etc.

Liquid Silicone Rubber Product Reference:

| Appearance | A component: transparent floating liquid |

| B component: transparent floating liquid | |

| Viscosity (Pa.s) | 58 |

| Mixing ratio | A:B=1:1 |

| Operation time ([email protected]ºC) | 3H |

| Operation time ([email protected]ºC) | 1.5H |

| Heat curing time ([email protected]ºC-160ºC) | 56s |

| Tensile strength Mpa | 6.1 |

| Tearing strength N/mm | 28 |

| Elongation % | 300 |

| Hardness (Shore A) | 50 Shore A |

| Vulcanizing condition | 25ºC×24H or 60ºC×2H |

| Volume Resistivity Ω.cm | 1×10 |

| dielectric strength KV/mm | 20 |

Liquid Silicon Rubber-Five Features:

Liquid Silicon Rubber-physical formLSR----liquid state with liquidityLiquid Silicon Rubber-applicationsLiquid Silicon is food-grade and skin-friendly, which can contact food and human body directly. But its application is limited, mainly in infant series, kitchen wares and medical products.Liquid Silicon Rubber-safetyLiquid Silicon Rubber is a kind of high transparent and safe food-grade material through closed batch charging forming, without adding vulcanizing agents during molding.Liquid Silicon Rubber-forming methodLiquid Silicon Rubber is also called Injection Molding Liquid Silicone Rubber (LSR) and the curing equipment is Injection molding machine. More simple technical process and higher-level automation, preciser product size and higher productivity are main advantages of Liquid Silicone.Liquid Silicon Rubber productsLiquid silicone products is high transparent and odorless, with injection gate.

Xiamen Better Silicone Rubber Co., Ltd, not only can make rubber compression tooling & plastic injection molding, produce silicone rubber compression parts & products, but also can make liquid silicone rubber injection mold and produce liquid silicone products.Four production plants:Mold-Making PlantsSilicone Rubber Compression PlantPlastic Injection PlantLiquid Silicone Rubber Injection Plant.

Compression silicon rubber molded parts tolerance, can be +/- 0.02mm, like for medical device, smart cell phone, electronic and so on.Our company not only can produce normal precision liquid silicone rubber products, but also can make metal + liquid silicone & plastic + liquid silicone rubber over-molding products.

Our Contact

Send now